P Id Piping Instrumentation Diagram

Piping and instrumentation diagram documentation criteria april 2008 1.

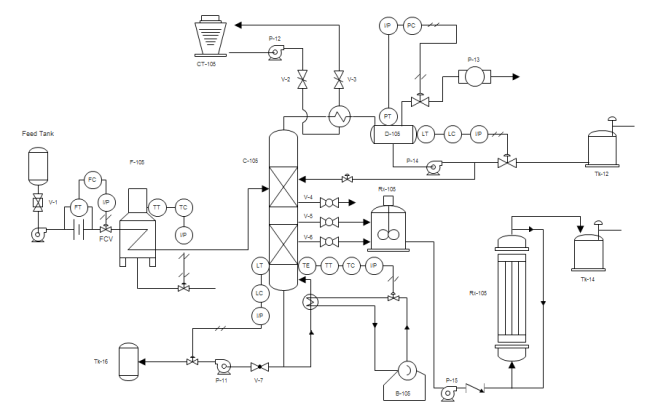

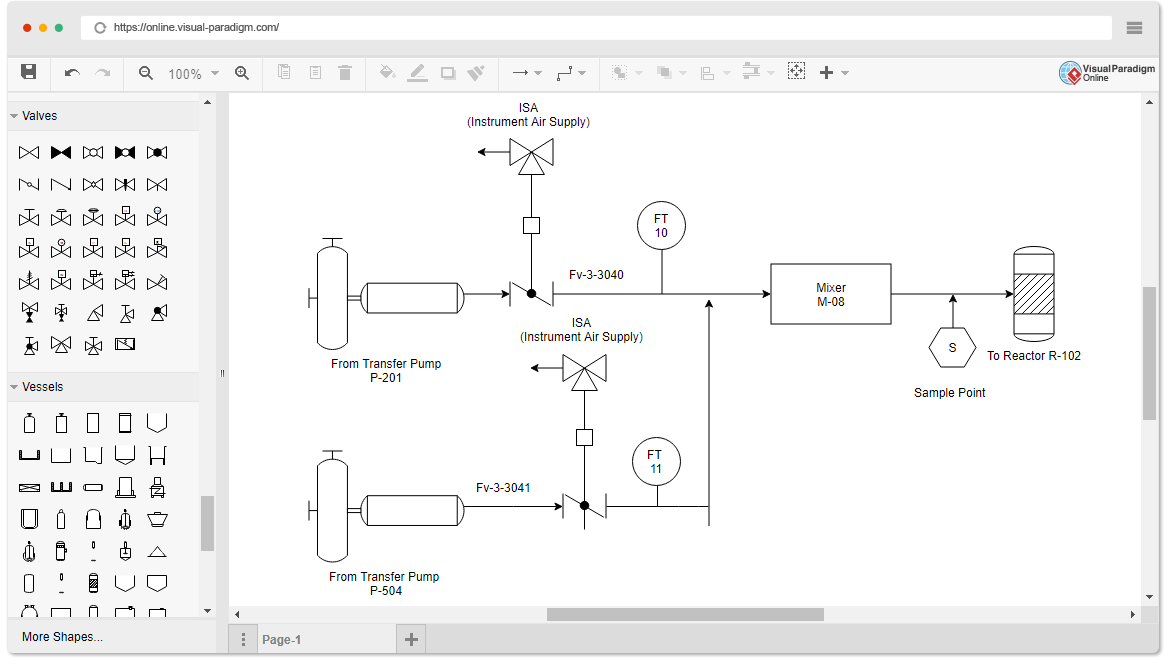

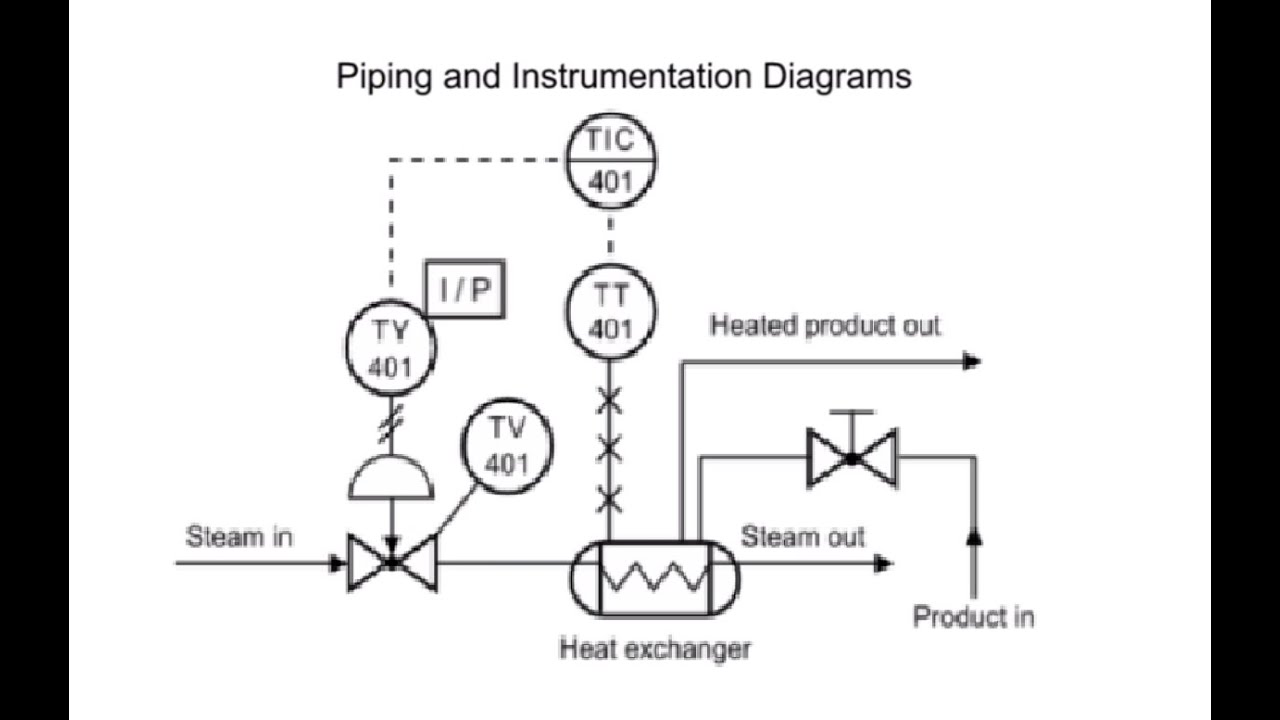

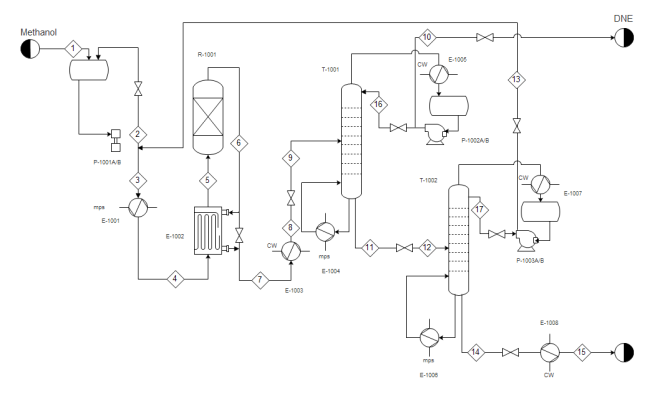

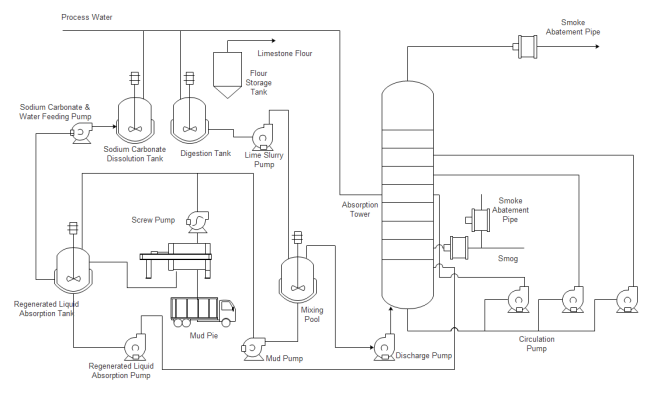

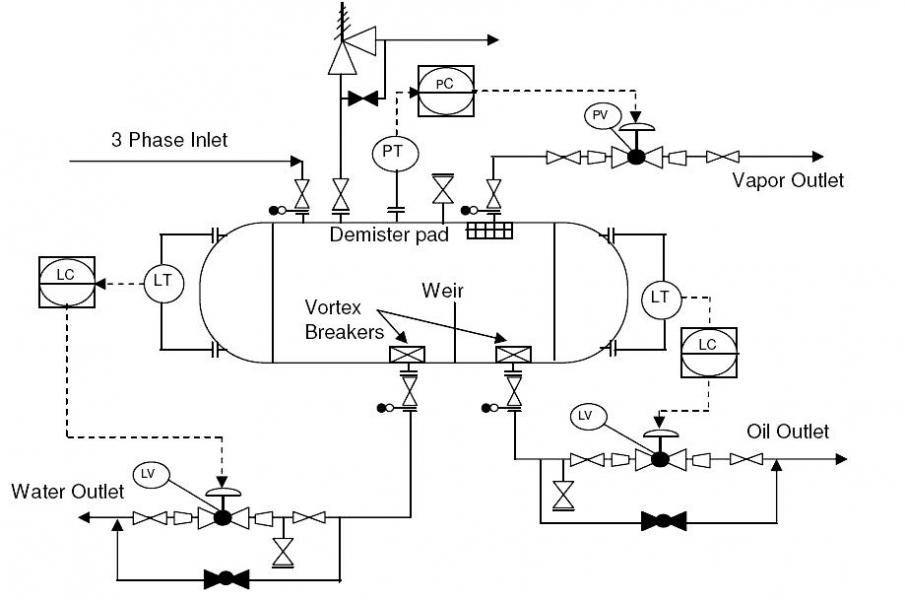

P id piping instrumentation diagram. All valves and their. For example basic orconceptual designs often named process flow diagrams pfd offer fewer detailthan completely developed piping and instrumentation diagrams pids. A pid should include. A pid shows all piping including the physical sequence of branches reducers valves equipment instrumentation and control interlocks.

The pids are used to operate process systems. A piping and instrumentation diagram pid is a drawing in the process industry. Its most commonly used in the engineering field. Pids shows all piping including physical sequences of branches reducers valves equipment instrumentation and control interlocks.

The p id includes every mechanical aspect of the plant except stream flows pipe routing pipe lengths pipe fittings supports structure foundations. A piping and instrumentation diagram pid is defined by the institute of instrumentation and control as follows. It includes all piping instruments valves and equipment that the system consist of. A process and instrumentation diagram p id shows the process flow and interconnection of process equipment which is used control a process.

Instrumentation detail varies withthe degree of design requirement and project phase. Pids are often used in the process industry to show the process flow and other installed equipment and instrument. In the process industry a standard set of symbols is used to prepare drawings of processes. Function and purpose of pids.

Mechanical equipment with names and numbers. Introduction 11 purpose this practice provides requirements for designers preparing piping and instrumentation diagrams pids. A diagram which shows the interconnection of process equipment and the instrumentation used to control the process. 12 scope this practice describes the requirements for pid format and content.

A piping and instrumentation diagram or pid shows the piping and related components of a physical process flow.