Leader Standard Work Template

Download leader standard work template best standard work instruction professional from standard work template examples with resolution.

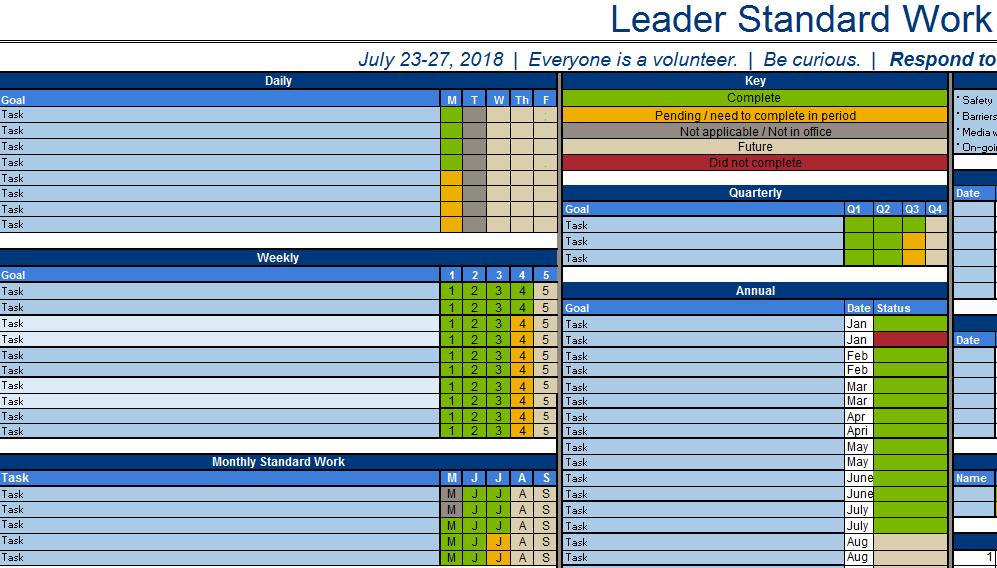

Leader standard work template. Leader standard work for managers and directors. Leader standard work definition example template and advice leader standard work. A lean organization is driven by its standards. This is intended for model line managers and directors who are on the certification track to deeply understand the methods of change leadership and application of lean to their areas of responsibility and support.

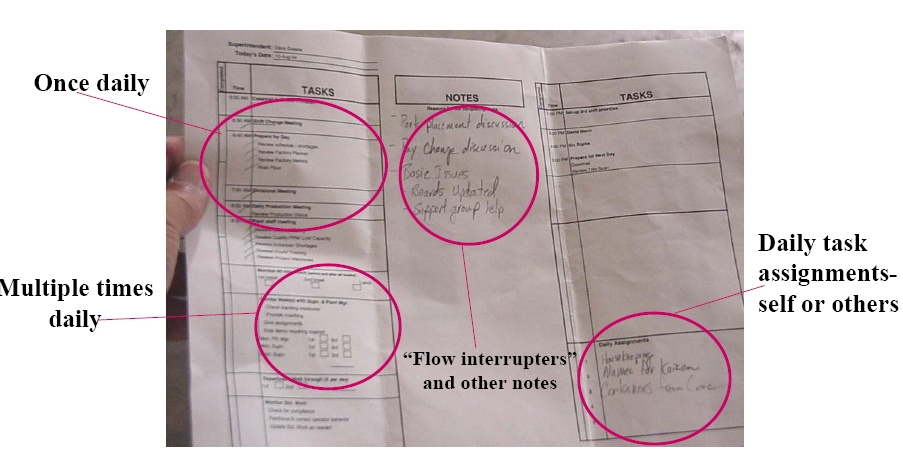

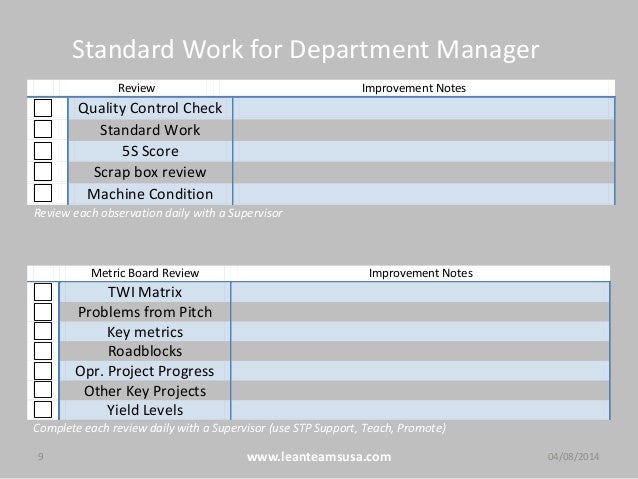

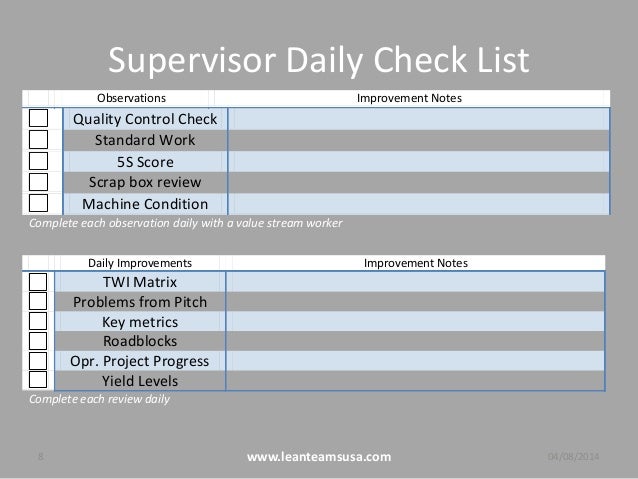

Operational rounding leader rounding service rounding etc conduct purposeful genba observations supported by lean tools recognition review satisfaction results patient and staff conduct daily huddle with standard work review sign genba production board throughout the day sweep work environmentfacility. The leader is responsible to ensure that each item is present on the production board and discussed during the huddle. Do it in a way that is standardized repeatable and teachable across a large enterprise that might span the globe. Personalize their own standard work with all the power flexibility and familiarity of microsoft excel.

Model line leadership training for managers and directors. Used when a leadership role is shared across different shiftsdays. Leader standard work promotes process focus instead of people focus. Your leader standard work template provides a system for the leaders within your organization to.

Leader standard work encourages communication and collaboration to fix process problems. Leader standard work lean system and templates for a sturdy teachable repeatable lean administration system. Here are three benefits to leader standard work. Team leader standard work.

More than just a template. Supervisor leader standard work. 695 x 811 pixel. 2048 x 1402 pixel.

For supporting functions and managers defining standard work can be more challenging especially since their work cannot be planned 100. Leader standard work enhances event driven process improvement. Standard operating procedures are used for production staff to describe was needs to be done and how to do it.