Haccp Certification Meaning

Good manufacturing practice gmp and hazard analysis and critical control points haccp are both systems intended to ensure the safety of food chemicals and pharmaceuticals.

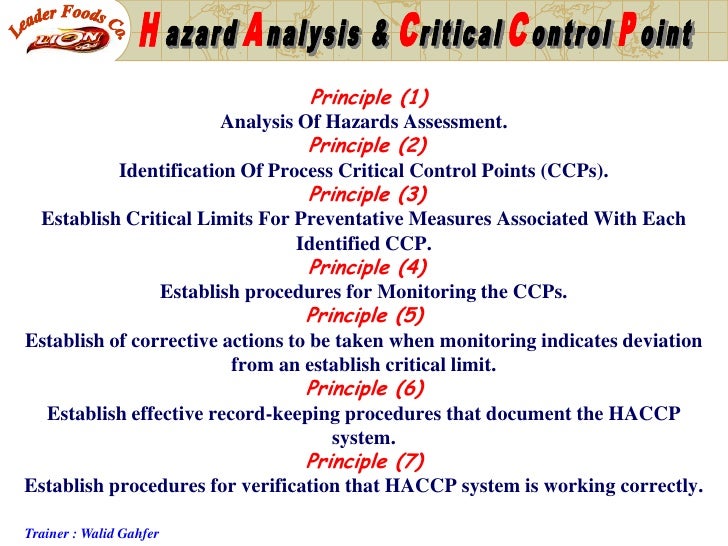

Haccp certification meaning. Hazard analysis and critical control points or haccp haesp is a systematic preventive approach to food safety from biological chemical and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. Gmp is the first step to food safety as a series of principles to be fulfilled to ensure that products meet legal prerequisites for safety and quality. Hazard analysis and critical control point. The hazard analysis and critical control point also known as the haccp is a system of safety in food production and pharmaceuticals.

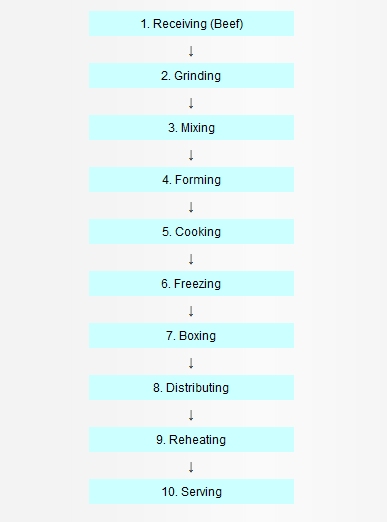

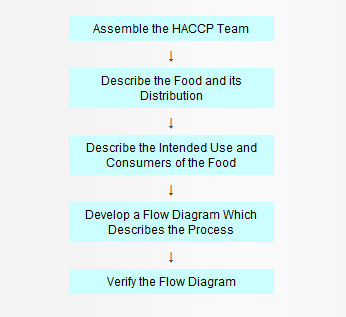

Haccp is a management system in which food safety is addressed through the analysis and control of biological chemical and physical hazards from raw material production procurement and handling to manufacturing distribution and consumption of the finished product. This includes biological chemical or physical hazardsany company involved in the manufacturing. It is built around seven principles. Food production storage and distribution monitoring system for identification and control of associated health hazards.

It is aimed at prevention of. Conduct hazard analysis of biological chemical or physical food hazards. Haccp is an internationally recognized system for reducing the risk of safety hazards in food. A haccp system requires that potential hazards are identified and controlled at specific points in the process.

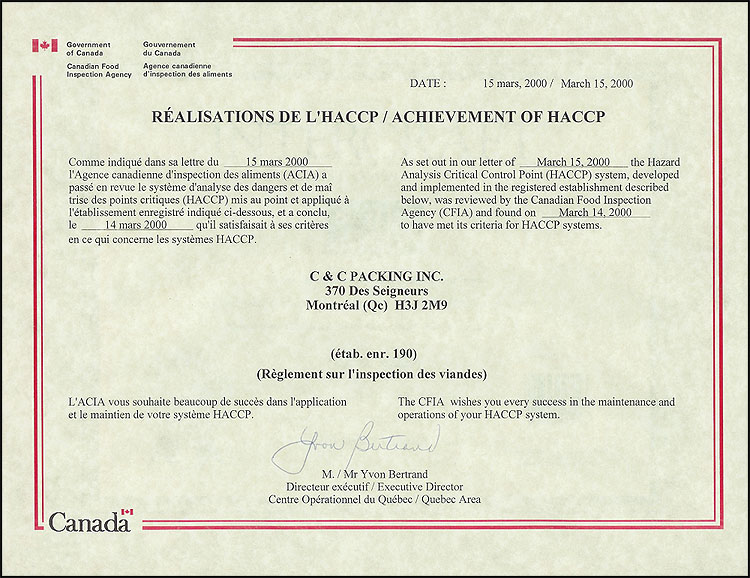

Haccp certification is a system that recognises that a food business has developed documented and implemented systems and procedures in accordance with haccp. The implementation of the hazard analysis and critical control point haccp rule and fsis laboratory testing programs are two areas that help ensure the safety of the meat poultry and egg products supply.